With their innovative design and reinforcement capabilities, brass coated micro steel fibers enhance the tensile strength and impact resistance of concrete structures. Consider their suitability for applications such as high-stress environments, crack control, and improved durability. By understanding the advantages of brass coated micro steel fiber, you can enhance the performance and lifespan of your concrete structures.

Features of Brass Coated Micro Steel Fiber

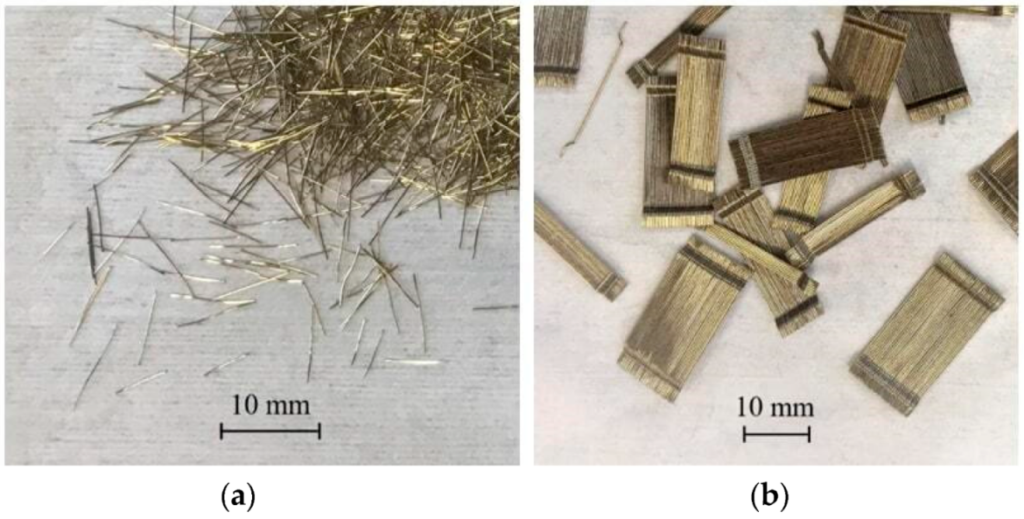

Brass coated micro steel fiber is a high-performance reinforcement material designed to enhance the strength and durability of concrete. These fibers consist of a fine steel wire core coated with a layer of brass, providing corrosion resistance and improved bonding with the concrete matrix. The small size and discrete nature of the fibers allow for easy dispersion within the concrete mixture, ensuring uniform reinforcement. Brass coated micro steel fibers offer excellent tensile strength, crack control, and impact resistance properties.

Applications of Brass Coated Micro Steel Fiber

Brass coated micro steel fiber finds extensive applications in various industries that require enhanced concrete performance. In construction, these fibers are used in high-stress areas such as industrial flooring, tunnel linings, and precast concrete elements to improve load-bearing capacity and reduce cracking. In infrastructure development, brass coated micro steel fiber reinforcement enhances the durability and longevity of bridges, highways, and airport runways, minimizing maintenance and repair costs. These fibers are also suitable for applications where increased impact resistance and resistance to dynamic loads are essential.

Advantages of Brass Coated Micro Steel Fiber

Brass coated micro steel fiber offers several advantages over traditional concrete reinforcement methods. The discrete nature of the fibers ensures homogeneous reinforcement throughout the concrete, improving crack control and reducing shrinkage. The brass coating provides excellent corrosion resistance, making these fibers suitable for harsh environments and exposure to chemicals. Brass coated micro steel fiber reinforcement also enhances the ductility and toughness of concrete, allowing it to withstand higher impact loads. Additionally, these fibers are easy to handle and disperse, making them convenient for various concrete applications.

Example: Brass Coated Micro Steel Fiber in Industrial Flooring

In industrial flooring applications, brass coated micro steel fiber reinforcement offers significant benefits. These fibers enhance the load-bearing capacity and impact resistance of the concrete, making it suitable for heavy machinery and high-traffic areas. For example, in warehouses and manufacturing facilities, the inclusion of brass coated micro steel fibers in the concrete flooring prevents cracks and surface failures, leading to reduced maintenance and repair costs. The reinforced flooring also ensures a safer working environment by minimizing the risk of trip hazards and structural failures.

Conclusion

In conclusion, brass coated micro steel fiber provides an effective solution for enhancing the strength and durability of concrete structures. With their innovative design, reinforcement capabilities, and diverse applications, these fibers are ideal for improving concrete performance in construction, infrastructure development, and industrial flooring. Consider the specific requirements of your project and the advantages of brass coated micro steel fiber, such as improved crack control, corrosion resistance, and increased impact resistance. By utilizing these fibers, you can enhance the strength, durability, and longevity of your concrete structures.