Learn how fiber mesh concrete has been successfully employed in various applications, from residential driveways to commercial infrastructure. Make informed decisions about incorporating fiber mesh concrete into your construction projects based on a comprehensive analysis of its pros and cons.

Pros of Fiber Mesh Concrete

Increased Crack Resistance:

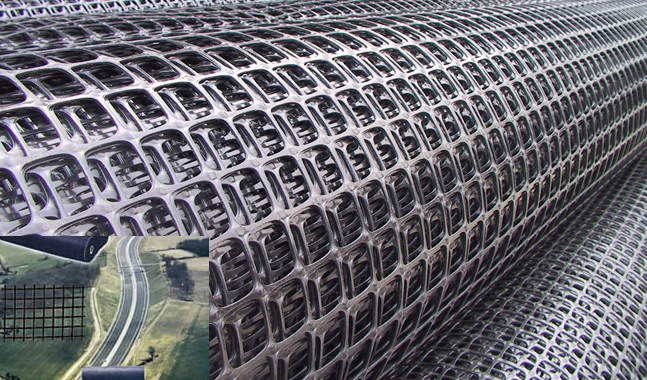

Fiber mesh concrete provides improved crack resistance compared to traditional concrete. The addition of synthetic or steel fibers reinforces the concrete matrix, reducing the risk of cracks caused by shrinkage, temperature fluctuations, or external loads. This enhanced crack resistance ensures structural integrity and prolongs the lifespan of concrete elements.

Improved Durability:

Fiber mesh reinforcement enhances the durability of concrete structures. The fibers distribute stress more evenly throughout the concrete, reducing the formation and propagation of cracks. This results in increased resistance to wear, impact, and weathering, making fiber mesh concrete suitable for high-traffic areas or structures exposed to harsh environmental conditions.

Enhanced Impact Resistance:

Fiber mesh concrete exhibits superior impact resistance due to the reinforcing fibers. The fibers absorb and dissipate energy upon impact, minimizing the formation of cracks and preventing the spread of damage. This property makes fiber mesh concrete ideal for applications such as industrial floors, pavements, and bridge decks that are subject to heavy loads or potential impact forces.

Cons of Fiber Mesh Concrete

Cost Considerations:

One of the main drawbacks of fiber mesh concrete is the additional cost associated with the inclusion of fibers. Compared to traditional concrete, fiber mesh concrete can be more expensive due to the cost of the fibers and the potential need for specialized mixing and installation techniques. Construction project budgets need to account for these added expenses.

Installation and Compatibility Challenges:

Fiber mesh concrete requires proper mixing and installation techniques to ensure the effective dispersion and alignment of fibers throughout the concrete matrix. Inadequate mixing or improper fiber distribution can result in reduced performance and compromised structural integrity. Additionally, the compatibility of fiber mesh concrete with certain admixtures and finishing techniques may need to be carefully evaluated and tested.

Examples of Fiber Mesh Concrete Applications

Residential Driveways:

Fiber mesh concrete is commonly used in residential driveways to enhance durability and minimize cracking. The fiber reinforcement helps withstand the weight of vehicles and provides resistance to freeze-thaw cycles and seasonal temperature changes. This results in longer-lasting and more aesthetically pleasing driveways compared to traditional concrete.

Commercial Infrastructure:

Fiber mesh concrete finds extensive application in commercial infrastructure projects, including industrial floors, warehouse facilities, and parking structures. The added strength and crack resistance offered by fiber mesh reinforcement ensures the longevity and structural integrity of these high-traffic areas, reducing maintenance costs and enhancing safety.

Conclusion

In conclusion, fiber mesh concrete offers several advantages and disadvantages in construction projects. The inclusion of fibers enhances crack resistance, improves durability, and increases impact resistance. However, the additional cost and installation challenges associated with fiber mesh concrete should be carefully considered. By evaluating the pros and cons, construction professionals can make informed decisions about incorporating fiber mesh concrete into their projects. With the right application and proper installation techniques, fiber mesh concrete can deliver long-lasting, resilient, and structurally sound results.