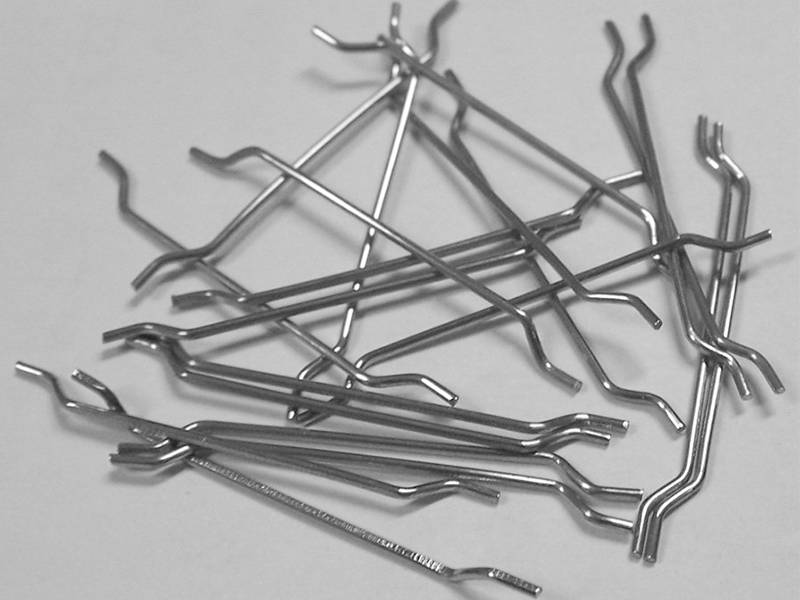

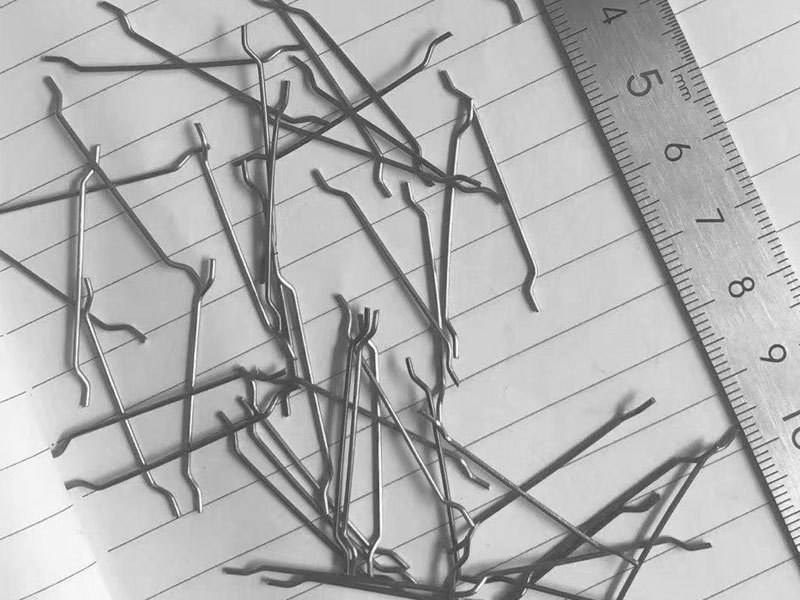

Hooked steel fibers are widely used in concrete construction for their exceptional features, including improved crack resistance, flexural strength, and durability. This comprehensive article delves into the key features of hooked steel fibers, providing valuable insights for professionals seeking optimal concrete reinforcement solutions.

Introduction:

Hooked steel fibers are a popular choice for concrete reinforcement due to their exceptional features and benefits. This article explores the key hooked steel fibers features, making it an essential reading for professionals seeking to optimize their concrete performance.

Key Features of Hooked Steel Fibers

Hooked steel fibers are known for their exceptional features that enhance concrete performance, including:

- Crack Resistance: The hooked shape of the fibers provides a mechanical bond with the concrete, improving crack resistance and preventing the propagation of cracks.

- Flexural Strength: Hooked steel fibers improve the flexural strength of concrete, allowing it to withstand greater loads and stresses.

- Durability: Hooked steel fibers improve the durability of concrete, making it more resistant to wear, tear, and environmental factors such as temperature changes and moisture.

Benefits of Using Hooked Steel Fibers in Concrete Construction

Using hooked steel fibers in concrete construction provides various benefits, including:

- Improved Performance: Hooked steel fibers enhance concrete performance, improving its crack resistance, flexural strength, and durability.

- Cost-Effective: Using hooked steel fibers can be a cost-effective concrete reinforcement solution, as it eliminates the need for additional reinforcement materials and reduces maintenance costs.

- Easy to Use: Hooked steel fibers are easy to use and can be added to concrete mixes without significant modifications to the production process.

Applications of Hooked Steel Fibers in Concrete Construction

Hooked steel fibers are widely used in various concrete construction applications, including:

- Industrial Flooring: Hooked steel fibers are used in industrial flooring applications to improve durability and resistance to heavy loads and traffic.

- Precast Concrete: Hooked steel fibers are used in the production of precast concrete elements such as pipes, panels, and retaining walls, improving their strength and durability.

- Shotcrete: Hooked steel fibers are used in shotcrete applications, providing enhanced performance and durability in tunneling, mining, and slope stabilization projects.

Practical Examples of Hooked Steel Fiber Applications:

- Airport Runways: Hooked steel fibers are used in the construction of airport runways to improve their durability and resistance to heavy loads and traffic.

- Industrial Warehouses: Hooked steel fibers are used in the construction of industrial warehouses to enhance durability and resistance to heavy loads and traffic.

- Bridge Decks: Hooked steel fibers are used in the construction of bridge decks, improving their crack resistance, flexural strength, and durability.

In conclusion, hooked steel fibers are an excellent option for concrete reinforcement due to their exceptional features and benefits. By improving crack resistance, flexural strength, and durability, they enhance concrete performance and provide a cost-effective and easy-to-use solution for professionals seeking optimal concrete reinforcement solutions. By incorporating hooked steel fibers into their projects, professionals can achieve enhanced performance and durability, contributing to long-lasting and efficient operation.