This article explores the benefits of using stainless steel fiber reinforced concrete (SSFRC) in construction projects. SSFRC offers improved strength, crack resistance, and durability compared to traditional concrete. The article discusses the working principle, advantages, and applications of SSFRC, showcasing its effectiveness in various structural elements. By understanding the value of SSFRC, engineers and contractors can make informed decisions to enhance the longevity and performance of concrete structures.

Stainless steel fiber reinforced concrete (SSFRC) is an innovative and high-performance construction material that offers enhanced strength and durability compared to conventional concrete. This article delves into the advantages of using SSFRC, highlighting its unique properties, applications, and the positive impact it has on concrete structures.

Introduction to Stainless Steel Fiber Reinforced Concrete

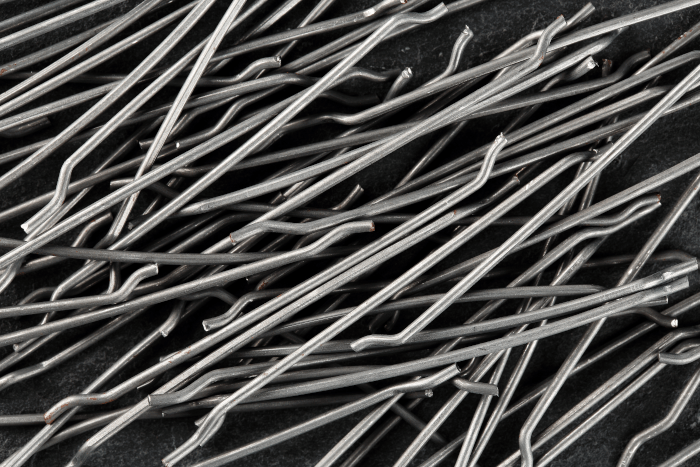

Stainless steel fiber reinforced concrete is a specialized form of concrete that incorporates small, discrete stainless steel fibers into the mix. These fibers, typically in the range of 0.25% to 2% by volume, significantly improve the mechanical properties of the concrete, resulting in enhanced performance and longevity of the structure.

Advantages and Applications of Stainless Steel Fiber Reinforced Concrete

- Increased Flexural and Tensile Strength: The addition of stainless steel fibers enhance the flexural and tensile strength of concrete, making it more resistant to cracking and structural failure. This reinforcement is particularly beneficial in applications such as bridge decks, industrial floors, and precast elements.

- Improved Crack Resistance: Stainless steel fibers act as reinforcement throughout the concrete matrix, reducing the width and propagation of cracks. This feature is valuable in structures subjected to dynamic loads, temperature variations, and harsh environmental conditions.

- Enhanced Durability: SSFRC exhibits excellent corrosion resistance, making it suitable for use in marine environments or structures exposed to chloride ions. It also provides improved resistance to impact, abrasion, and fatigue, ensuring the longevity and durability of the concrete elements.

- Design Flexibility: SSFRC offers greater design flexibility compared to traditional concrete. The addition of stainless steel fibers allows for thinner and lighter structural elements, reducing material usage and construction costs while maintaining structural integrity.

Future Trends and Innovations in Stainless Steel Fiber Reinforced Concrete

The future of stainless steel fiber reinforced concrete is marked by ongoing advancements and innovations. Efforts are underway to develop new fiber geometries, optimize fiber dosage, and explore the use of alternative materials. Additionally, the integration of advanced testing methods and computer modeling is enabling more accurate predictions of structural behavior and performance.

Furthermore, there is a growing emphasis on sustainable construction practices, leading to the exploration of eco-friendly fibers and mixed designs. These innovations aim to enhance the environmental profile of stainless steel fiber reinforced concrete while maintaining its high-performance characteristics.

Conclusion:

Stainless steel fiber reinforced concrete offers significant advantages in terms of strength, crack resistance, and durability. Its unique properties make it an ideal choice for various construction applications. By leveraging the benefits of stainless steel fiber reinforced concrete, engineers and contractors can enhance the performance, longevity, and sustainability of concrete structures. With ongoing research and innovation, the future of SSFRC holds promise for even more efficient and resilient construction practices.