A filter press is a piece of equipment used in various industries to separate liquids from solids. It is a versatile tool that can be used for a wide range of applications, from wastewater treatment to food and beverage production. In this article, we will explore what a filter press is, how it works, and its different types.

How Does a Filter Press Work?

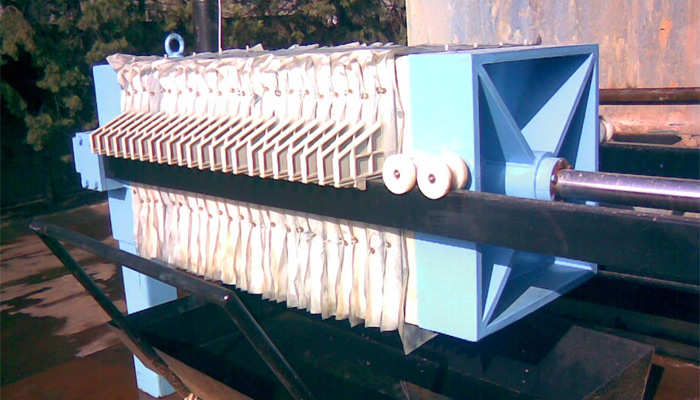

What is a filter press? Filter press consists of a series of plates and frames that are stacked together to form a chamber. The plates have holes in them, which allow the liquid to pass through while the solids are collected on the surface of the plates.

The liquid is fed into the chamber and flows through the plates, leaving the solids behind. The solids are then removed from the plates and the liquid is discharged from the filter press.

The filter press works by using a combination of gravity and pressure to separate the liquids and solids. The pressure is applied to the chamber by a hydraulic system, which squeezes the solids and forces the liquid through the plates. The gravity helps to pull the liquid through the plates and out of the filter press.

Types of Filter Presses

There are several types of filter presses available, each with its unique characteristics and uses. Some of the most common types include:

1. Plate and Frame Filter Press

This is the most common type of filter press. It consists of a series of plates and frames that are stacked together to form a chamber. The plates have holes in them, which allow the liquid to pass through while the solids are collected on the surface of the plates.

2. Chamber Filter Press

This type of filter press is similar to the plate and frame filter press, but it has a larger chamber. This allows for a higher volume of liquid to be processed at one time.

3. Membrane Filter Press

This type of filter press uses a membrane instead of plates and frames. The membrane is designed to filter out specific particles or contaminants from the liquid.

4. Rotary Filter Press

This type of filter press uses a rotating drum to filter the liquid. The drum is divided into sections, each with its own set of plates and filters. The liquid is fed into the drum and flows through the plates and filters, leaving the solids behind.

Advantages of Using a Filter Press

There are several advantages to using a filter press. Some of the most significant benefits include:

1. High Efficiency

Filter presses are highly efficient and can filter large volumes of liquid quickly and effectively.

2. Low Maintenance

Filter presses are relatively low maintenance, as they have few moving parts and are designed to be easy to clean and maintain.

3. Versatility

Filter presses can be used in a wide range of industries and applications, from wastewater treatment to food and beverage production.

4. Cost-Effective

Filter presses are a cost-effective way to separate liquids and solids, as they do not require the use of chemicals or other expensive equipment.

Conclusion

In conclusion, a filter press is a versatile piece of equipment that is used in various industries to separate liquids from solids. It works by using a combination of gravity and pressure to filter the liquid through a series of plates and frames. There are several types of filter presses available, each with its unique characteristics and uses. Some of the advantages of using a filter press include high efficiency, low maintenance, versatility, and cost-effectiveness.