Explore the intricate process behind the manufacturing of steel fiber. This article delves into the steps involved in producing steel fiber, highlighting the materials, equipment, and techniques used. From raw materials to finished products, understanding the steel fiber manufacturing process is crucial for industries that require reinforced concrete and other applications that demand exceptional strength and durability.

Understanding the Steel Fiber Manufacturing Process

The steel fiber manufacturing process involves several crucial steps that transform raw materials into durable and high-performance reinforcement. From material selection to fiber formation and surface treatment, each stage contributes to the quality and characteristics of the final product.

Steps in the Steel Fiber Manufacturing Process

- Material Selection: The manufacturing process begins with carefully selected raw materials, typically low carbon steel or stainless steel. The choice of material depends on the desired properties of the steel fiber, including tensile strength and corrosion resistance.

- Melting and Casting: The selected steel material is melted in a furnace, and the molten steel is cast into thin strands or billets. These initial forms serve as the basis for the subsequent fiber formation process.

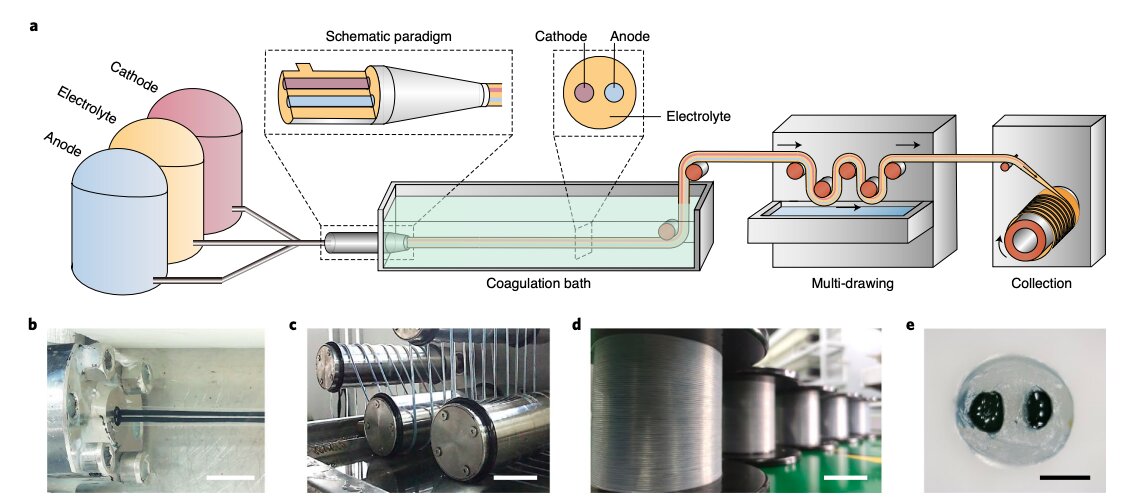

- Fiber Formation: The cast steel strands or billets are mechanically processed through a specialized machine that cuts or draws them into the desired fiber shape and length. The process ensures uniformity and consistency in the steel fiber dimensions.

- Surface Treatment: To enhance the bonding properties of the steel fiber with the surrounding matrix, a surface treatment is applied. This treatment can involve heat treatment, pickling, or coating the fibers with a protective layer.

- Quality Control: Throughout the manufacturing process, stringent quality control measures are implemented to ensure the steel fibers meet the required specifications. Testing for tensile strength, dimensions, and other parameters ensures the production of high-quality steel fibers.

Applications and Benefits of Steel Fibers

Steel fibers find extensive use in various industries, including construction, infrastructure, and industrial flooring. The addition of steel fibers to concrete enhances its mechanical properties, including flexural strength, impact resistance, and crack control. The result is stronger and more durable structures that can withstand heavy loads, seismic activity, and harsh environmental conditions.

Transition: Now, let’s explore real-world examples where the steel fiber manufacturing process has proven its effectiveness.

Example 1:

In the construction of high-rise buildings, steel fiber-reinforced concrete is utilized for structural elements such as columns and beams. The steel fibers enhance the concrete’s tensile strength, allowing for increased load-bearing capacity and improved structural integrity.

Example 2:

Industrial flooring systems, such as warehouses and manufacturing facilities, benefit from steel fiber reinforcement. The steel fibers improve the resistance to heavy traffic, impact, and abrasion, resulting in durable and long-lasting flooring solutions.

Conclusion:

In conclusion, the steel fiber manufacturing process involves careful material selection, casting, fiber formation, surface treatment, and quality control measures. The resulting steel fibers offer exceptional strength and durability, making them an ideal choice for various applications that require reinforced concrete and enhanced structural performance. Understanding the steel fiber manufacturing process allows industries to make informed decisions when selecting reinforcement materials, leading to the construction of robust and resilient structures. By incorporating steel fibers into concrete, industries can achieve enhanced strength, improved crack control, and increased longevity, ensuring the longevity and safety of their projects.