Steel fibers are an essential component in reinforced concrete, providing improved mechanical properties and durability. The manufacturing process of steel fibers involves several stages, including production, treatment, and cutting. In this article, we will explore the steel fiber manufacturing process, its properties, and design considerations for reinforced concrete.

Production of Steel Fibers

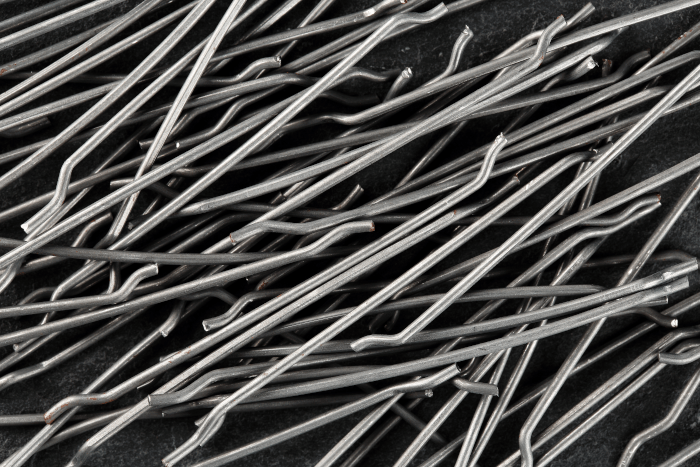

Steel fibers are produced through a process known as “drawing.” This process involves pulling a steel wire through a series of dies to reduce its diameter and increase its length. The resulting fiber is then cut to the desired length, typically ranging from 10 to 50 mm.

Properties of Steel Fibers

Steel fibers have several properties that make them an ideal reinforcement material for concrete. They have high tensile strength, which allows them to withstand the high compressive forces in concrete. They also have high ductility, which enables them to absorb energy and reduce the risk of cracking. Additionally, steel fibers are resistant to corrosion, which is a significant advantage in harsh environments.

Design of Steel Fibers in Reinforced Concrete

The design of steel fibers in reinforced concrete involves selecting the appropriate type and quantity of fibers for a given application. The most common types of steel fibers used in reinforced concrete are deformed and smooth fibers. Deformed fibers have a ribbed or crushed surface, which provides a better grip between the fiber and concrete. Smooth fibers, on the other hand, have a smooth surface and are used in applications where high ductility is required.

The quantity of steel fibers used in reinforced concrete depends on several factors, including the type of concrete, the application, and the desired mechanical properties. Generally, the dosage of steel fibers ranges from 1 to 3% by volume of concrete.

Conclusion

Steel fibers are a critical component in reinforced concrete, providing improved mechanical properties and durability. The manufacturing process of steel fibers involves several stages, including production, treatment, and cutting. The properties of steel fibers, such as high tensile strength, ductility, and corrosion resistance, make them an ideal reinforcement material for concrete.

The design of steel fibers in reinforced concrete involves selecting the appropriate type and quantity of fibers for a given application. By understanding the steel fiber manufacturing process and its properties, engineers can design high-performance reinforced concrete structures that meet the demands of modern construction.