This article provides a comprehensive guide on choosing a filter press for the steel fiber manufacturing process. It covers the factors to consider, such as capacity, filtration area, and automation level. The article also discusses the benefits of using a filter press and provides an example of a successful implementation. By following this guide, manufacturers can make an informed decision and find the right filter press at a competitive price.

Introduction:

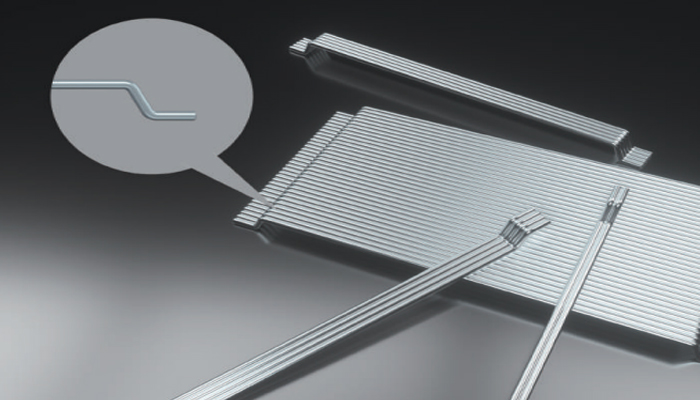

In the steel fiber manufacturing process, a filter press plays a crucial role in separating solids from liquids. Choosing the right filter press is essential for optimizing production efficiency and ensuring high-quality steel fibers. This article aims to guide manufacturers in selecting the most suitable filter press based on their specific needs and budget.

Factors to consider:

1. Capacity: The capacity of a filter press determines its ability to handle the required volume of slurry. Manufacturers should consider their production demands and choose a filter press with an adequate capacity.

2. Filtration area: The filtration area determines the speed and efficiency of the filtration process. A larger filtration area allows for faster filtration and higher throughput. Manufacturers should assess their production requirements and select a filter press with an appropriate filtration area.

3. Automation level: Filter presses come in manual, semi-automatic, and fully automatic variants. Manufacturers should consider the level of automation that best suits their production process. While manual filter presses are more affordable, automated ones offer higher efficiency and reduced labor costs.

Benefits of using a filter press:

1. Efficient solid-liquid separation: A filter press effectively separates solids from liquids, resulting in a high-quality filtrate and dry solids. This ensures the production of clean and pure steel fibers.

2. Cost-effective: By optimizing the filtration process, a filter press reduces waste and minimizes the use of chemicals. This leads to cost savings in terms of material and disposal expenses.

3. Environmental sustainability: Filter presses promote environmental sustainability by minimizing the discharge of pollutants into water bodies. The filtered water can be reused or safely discharged, reducing the impact on the environment.

Example:

Our Steel Fiber Manufacturing Company implemented a filter press with a high filtration area and fully automated operation. This allowed them to significantly increase their production capacity and improve the quality of their steel fibers. The automated features reduced labor costs and improved overall efficiency. As a result, our Steel Fiber Manufacturing Company saw a 30% increase in production output and a reduction in operating costs by 15%.

Conclusion:

Choosing the right filter press for the steel fiber manufacturing process is crucial for optimizing production efficiency and ensuring high-quality fibers. Manufacturers should consider factors such as capacity, filtration area, and automation level.

By selecting the most suitable filter press, manufacturers can achieve cost savings, environmental sustainability, and improved overall production output. It is recommended to thoroughly evaluate different options and consult with experts to make an informed decision.