Glued steel fibers, in particular, have gained popularity in recent years due to their numerous advantages. In this article, we will explore the benefits of using glued steel fibers in concrete and their applications in various structures.

Concrete is a versatile building material that has been used in construction for centuries. However, its weakness in tension and flexure has limited its application in certain structures. To overcome this limitation, steel fibers have been introduced to enhance the mechanical properties of concrete. G

What are Glued Steel Fibers?

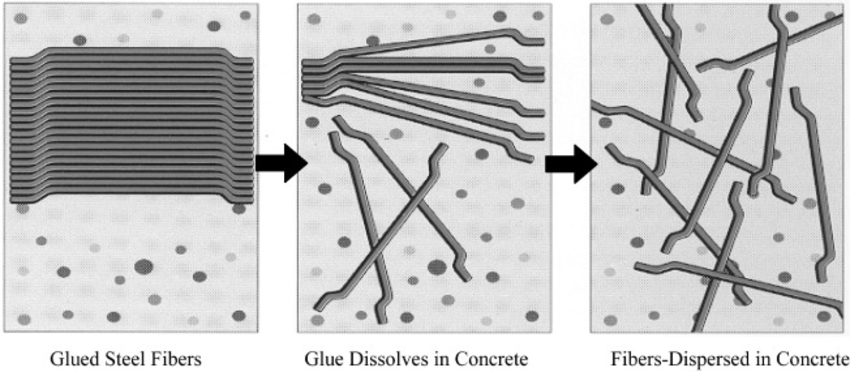

Glued steel fibers are thin, rectangular steel wires that are bonded to the concrete using an adhesive. They are available in various lengths, thicknesses, and shapes, and can be easily integrated into fresh concrete.

The adhesive used to bond the fibers to the concrete is designed to provide a strong and durable bond, ensuring that the fibers remain in place even under extreme loads.

Advantages of Glued Steel Fibers in Concrete

The use of glued steel fibers in concrete offers several advantages, including:

Improved Mechanical Properties: Glued steel fibers enhance the mechanical properties of concrete, including its tensile strength, flexural strength, and impact resistance. This makes it possible to use concrete in structures that require higher strength and durability.

Reduced Cracking: Steel fibers help to reduce cracking in concrete by absorbing and distributing stresses and strains. This reduces the risk of cracking and extends the lifespan of the structure.

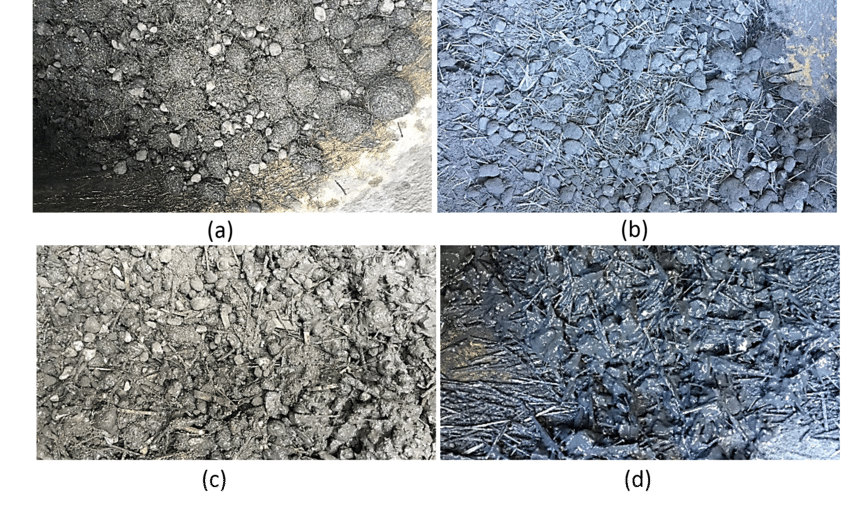

Improved Workability: Glued steel fibers improve the workability of concrete, making it easier to mix, pour, and finish. This reduces the risk of errors and defects and allows for smoother, more uniform finishes.

Increased Durability: Steel fibers improve the durability of concrete by reducing the risk of corrosion and abrasion. They also provide additional protection against environmental factors, such as UV radiation and chemical attack.

Cost-Effective: Glued steel fibers are a cost-effective solution for enhancing the mechanical properties of concrete. They are relatively inexpensive compared to other reinforcing materials and can be easily integrated into existing concrete production processes.

Applications of Glued Steel Fibers in Concrete

Glued steel fibers have a wide range of applications in various structures, including:

Building Foundations: Glued steel fibers are commonly used in building foundations to improve their strength and durability. They help to reduce settling and cracking and improve the overall stability of the structure.

Concrete Slabs: Steel fibers are often used in concrete slabs to improve their tensile strength and impact resistance. This makes them ideal for applications such as warehouse floors, parking garages, and airport runways.

Beams and Columns: Glued steel fibers are used in beams and columns to improve their flexural strength and compressive strength. This makes them suitable for use in structures such as bridges, high-rise buildings, and industrial facilities.

Water Tanks: Steel fibers are used in water tanks to improve their durability and resistance to corrosion. They help to reduce the risk of leaks and extend the lifespan of the tank.

Road construction: Glued steel fibers are used in road construction to improve the strength and durability of concrete pavements. They help to reduce cracking and rutting and improve the overall performance of the road.

Conclusion

Glued steel fibers are a versatile and effective way to enhance the mechanical properties of concrete. Their numerous advantages, including improved strength, reduced cracking, improved workability, increased durability, and cost-effectiveness, make them an ideal solution for a wide range of applications.

Whether you’re building a foundation, a slab, a beam, a column, a water tank, or a road, glued steel fibers are an excellent choice for ensuring the strength and durability of your structure.